Mrp And Erp Operations Management

Material requirements planning mrp is a production planning and inventory control system.

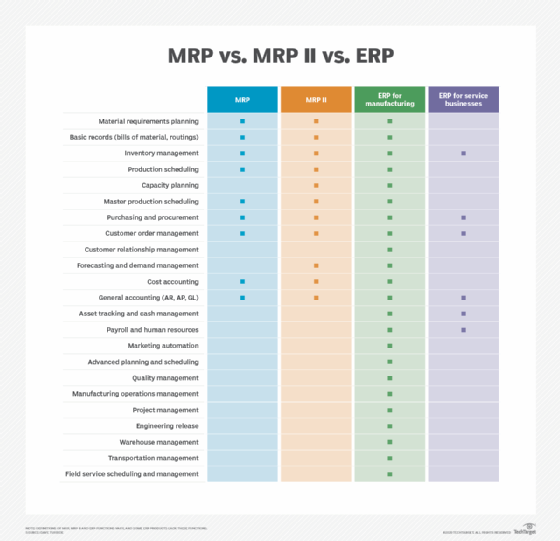

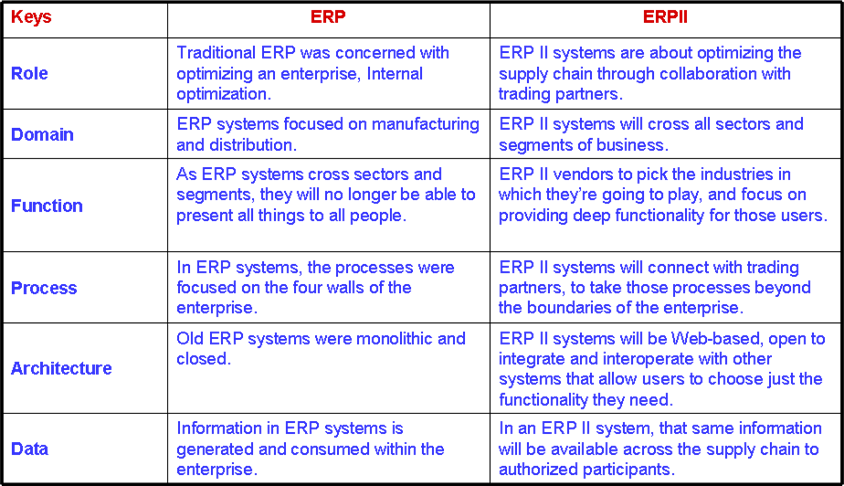

Mrp and erp operations management. Material requirements planning software only focuses on manufacturing whereas erp contains a range of solutions meant to ease diverse business processes such as accounting and hr. This increases the efficiency of production system. It stands for material requirements planning and it s a predecessor of erp solutions. Includes topics such as independent and dependent demand bill of material product structure tree mrp primary and secondary reports mrp 2 capacit.

Most mrp systems are software based but it is possible to conduct mrp by hand as well. Mrp may seem a weird abbreviation but it was a popular software solution just a few years ago. Material requirements planning mrp is a production planning scheduling and inventory control system used to manage manufacturing processes. Mrp provides a close coordination among various work centers and hence help to achieve uninterrupted flow of materials through the production line.

Mrp comprised three components. Erp systems require significant investments including. What is mrp in operations management. Material requirements planning is among the first software based.

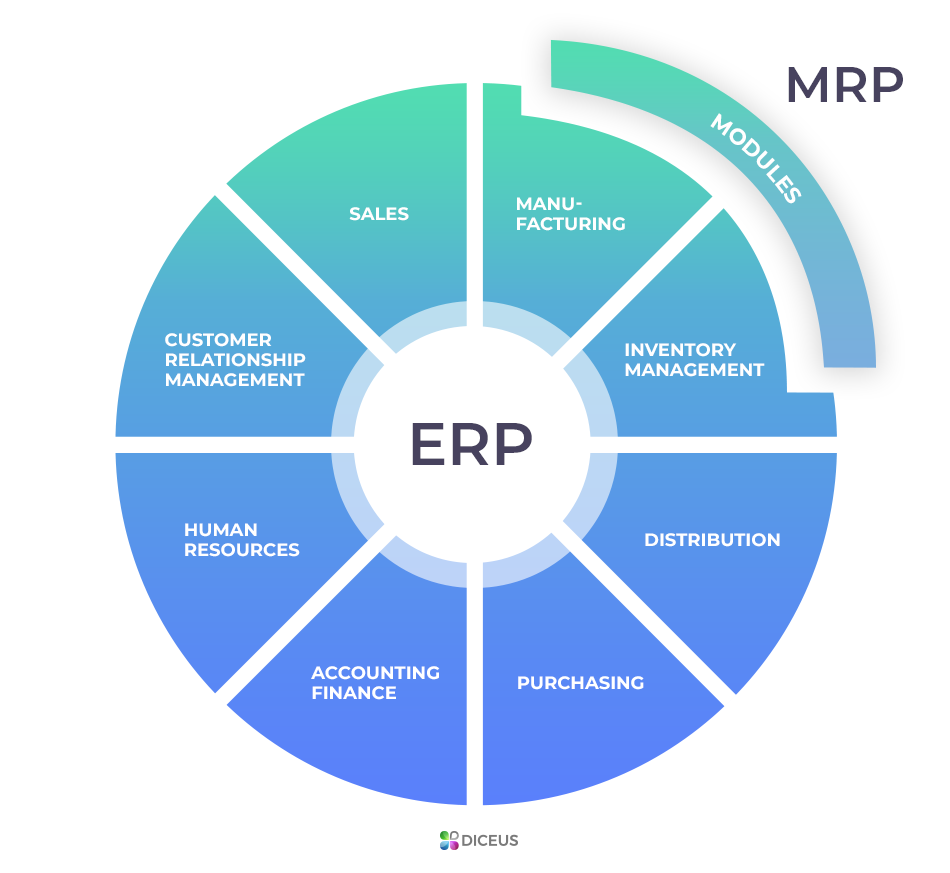

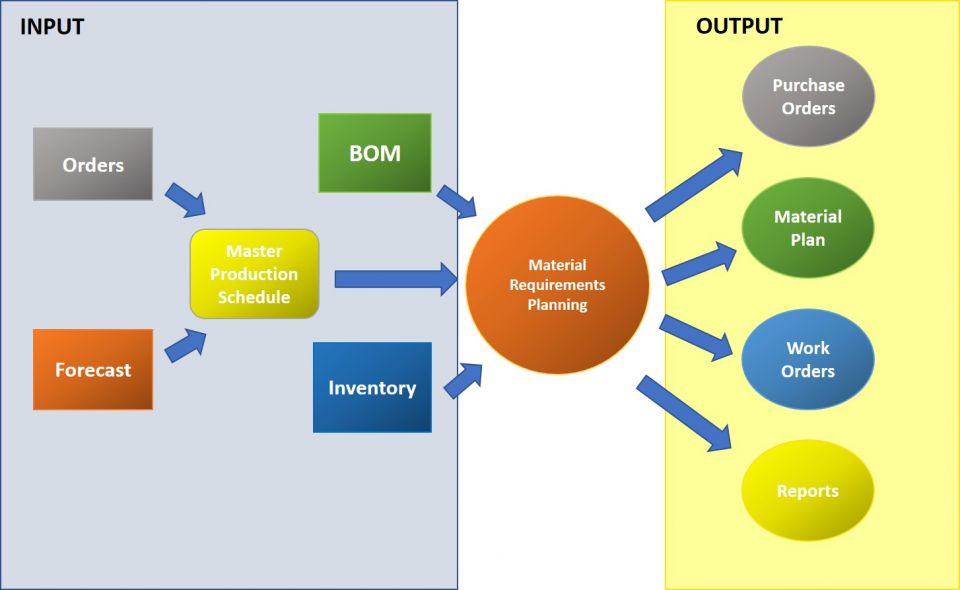

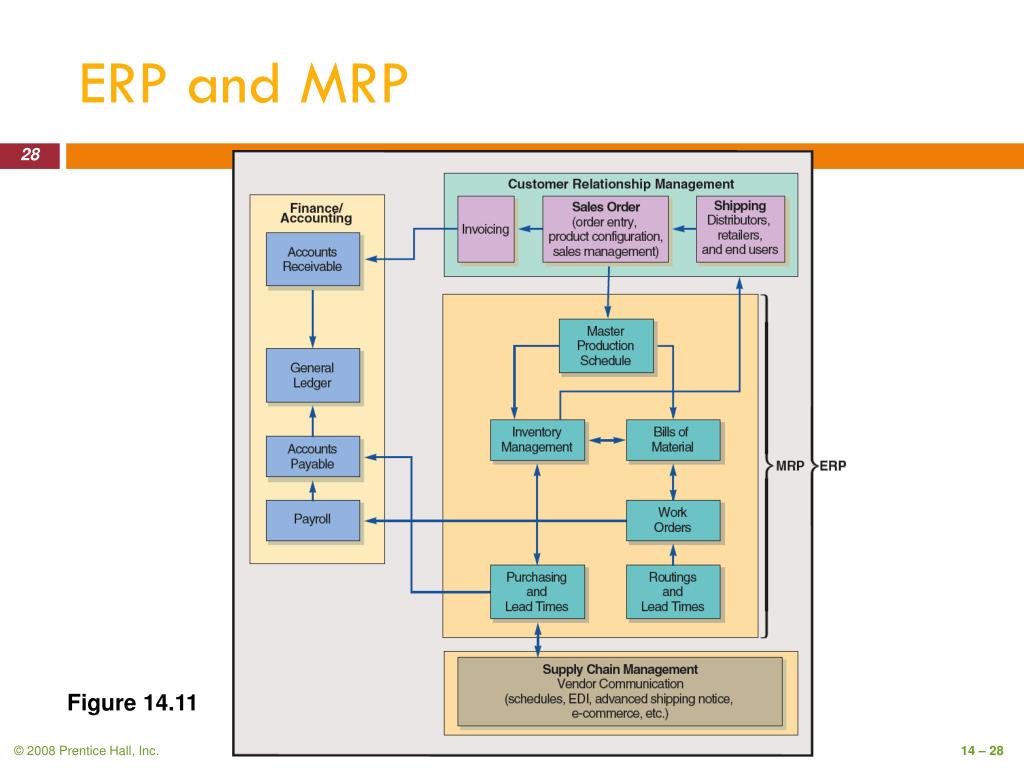

Case studies of successful enterprise resource planning. Mrp system the inputs to the mrp system are. Mrp is a crucial component of erp but depending on a company s needs it might not be the most critical process in the suite. Mrp is a computer based inventory management system designed to.

It was used mostly for managing the materials that were used for crafting new products. Start studying operations management chapter 12 mrp and erp. An mrp system is intended to simultaneously meet three objectives. An mrp integrates data from production schedules with that from inventory and the bill of materials bom to calculate purchasing and shipping schedules for the parts or components required to build a product.

Ensure raw materials are available for production and products are available for delivery to. Mrp is geared toward manufacturing operations while erp attempts to centralize the data and processes of an organization typically via a single computer system. Mrp any available stock is subtracted and lead times for the supply of components and the completion of finished products are estimated. An erp system has many advantages but beware of the silver bullet perception.