Just In Time Inventory Management System

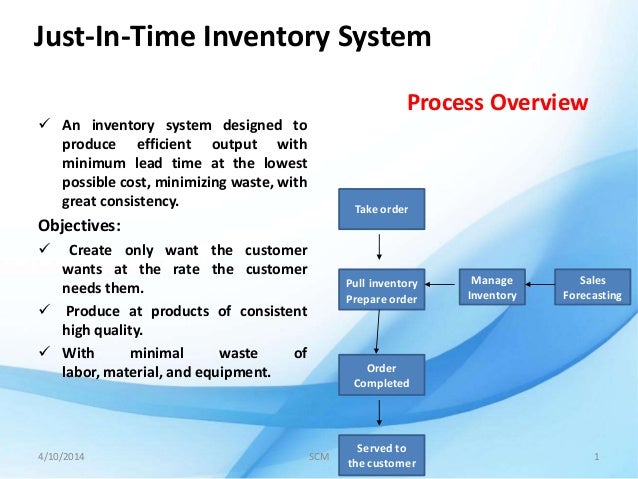

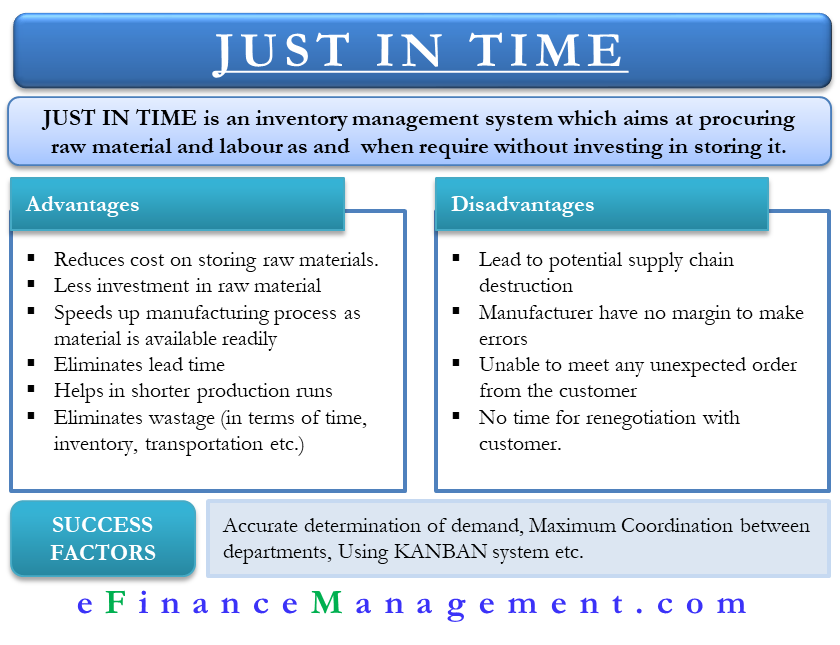

The concept refers to an inventory management system with the aims of having inventory readily available to meet production demand but not to a point of excess where.

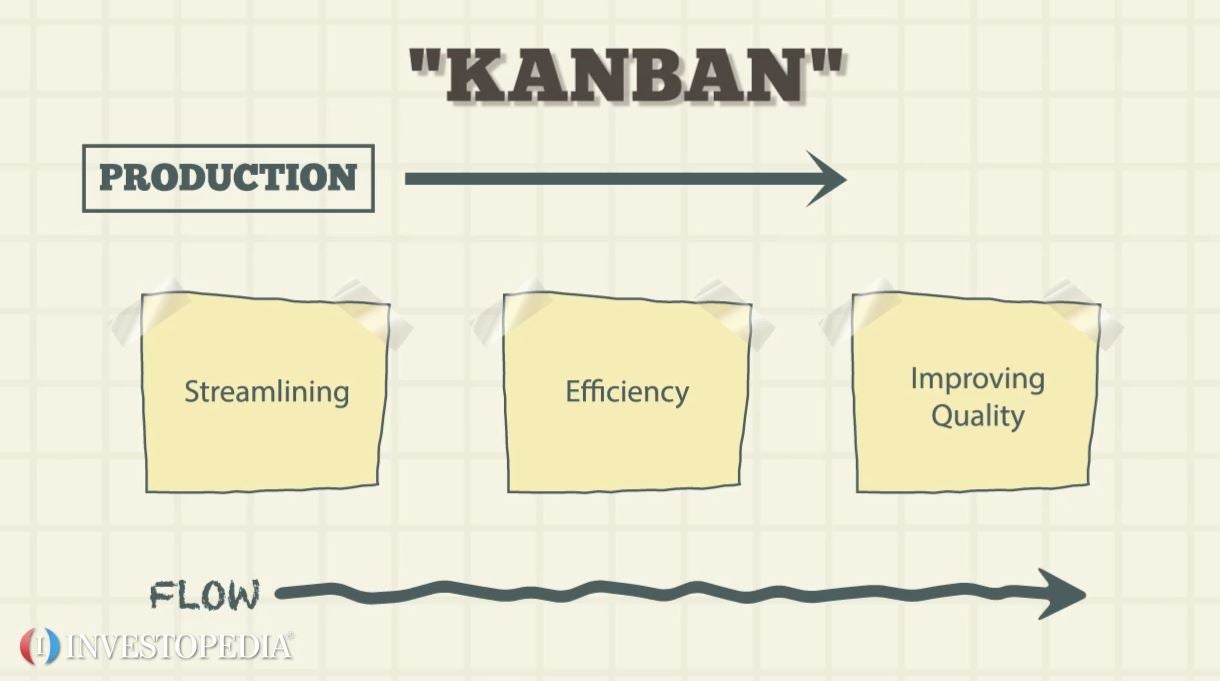

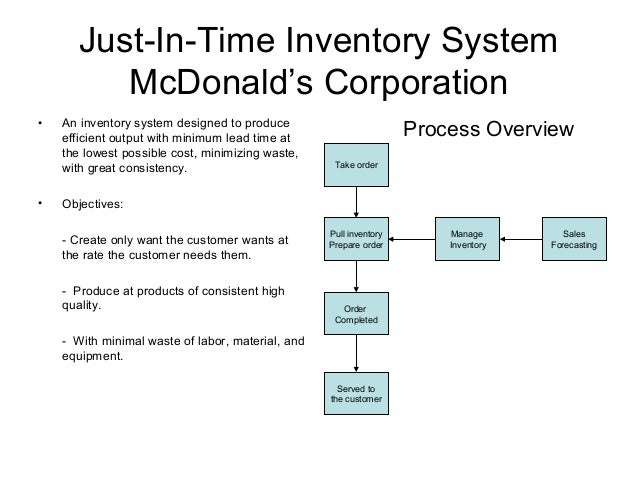

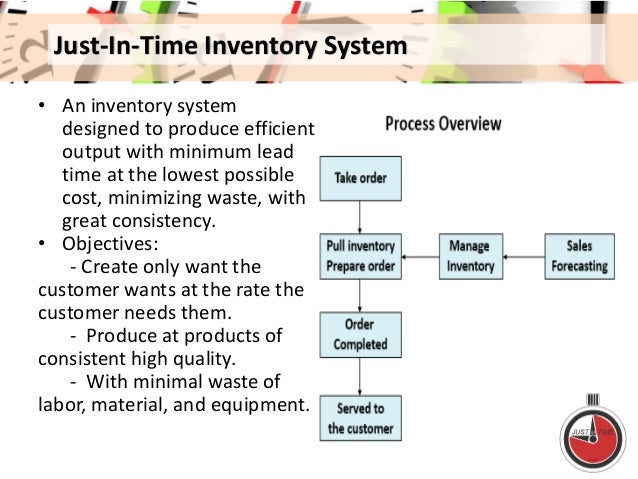

Just in time inventory management system. Jit was originally formed in japan as a response to the country s limited natural resources leaving little room for wastage. The just in time or jit is an inventory management system wherein the material or the products are produced and acquired just a few hours before they are put to use. Just in time jit inventory management also know as lean manufacturing and sometimes referred to as the toyota production system tps is an inventory strategy that manufacturers use to increase efficiency. Just in time or jit is an inventory management method in which you keep as little inventory on hand as possible.

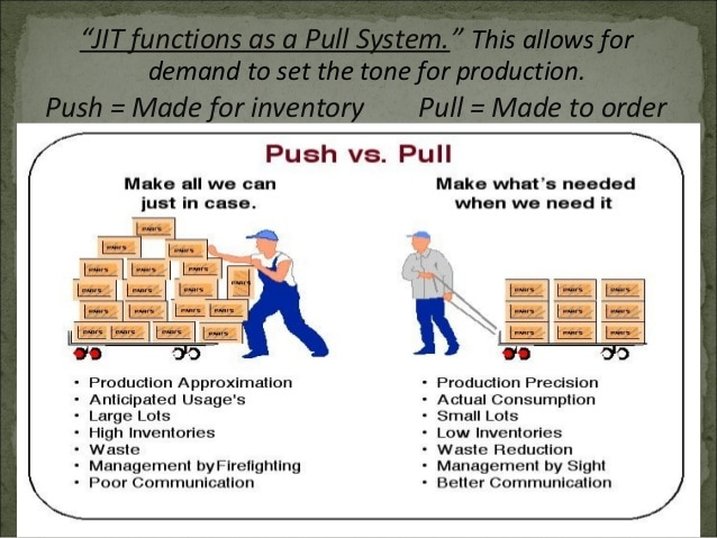

The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. The just in time jit inventory system is a management strategy that minimizes inventory and increases efficiency. The just in time system is adopted by the firms to reduce the unnecessary burden of inventory management in case the demand is less than the inventory raised. Just in time inventory can be defined as a strategy to increase production efficiency and decrease waste by receiving goods as and when required in the production process that results in the reduction of the inventory costs.

That means you don t stockpile products and raw materials just in case you need them you simply reorder products to replace those you ve already sold.

.jpg)

%20systems.jpg)